Click the button below to download the MVP Rebuild Kit PDF Rebuild Kits

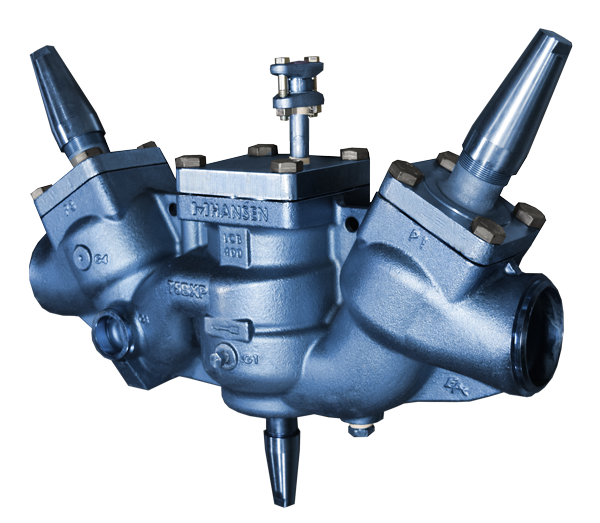

Rugged. Adaptable. Compact.

Ships pre-tested and assembled for quick and easy installation, requiring only two welds to complete most valve station applications.

No disassembly is required. Hansen control valve functions include solenoid valve, all common Hansen pressure regulator functions (inlet, outlet, dual pressure), Motorized Control Valve and gas powered suction stop (2 ½” – 4” port sizes). Can be configured using standard Hansen parts for most control functions.

The MVP is ideal for evaporator control: liquid feed, direct expansion, hot gas defrost and condensate relief, suction regulation and low temperature suction efficiency.

Also well suited for liquid feed to flooded and recirculator vessels, and liquid injection for screw compressors. Up to six separate functions are possible: stop valve, strainer, control valve (solenoid/pressure regulator/ motorized), check, hand expansion, and stop valve.

Installed cost savings is a huge advantage of the MVP valve. Faster installation, less pipe cutting, welding assembly time, insulation, and freight equal reduced costs. In addition, the compact valve body saves installation space and valve group weight. MVP valve includes up to six pressure taps to measure pressure at the inlet and outlet to the valve, as well as a ¾” NPT side connection.

TECHNICAL SPECIFICATIONS

Safe Working Pressure (MVP13 to MVP50): 600 PSIG (40 bar)

Safe Working Pressure (MVP65 to MVP100): 400 PSIG (28 bar)

Temperature Range: -60° to 240°F (-50º to 115ºC)

Materials Body: Forged steel (MVP13) or Cast Steel, ASTM A-352, grade LCB Bonnet: Ductile iron, ASTM A-536 FEATURES. 2 ½” – 4”: ACT® coated components standard.

Suitable for all Hansen approved refrigerants including R717, R134a, R404, R507 and CO2

Parts and parts kits same as Hansen individual valves – saves on stocking spare parts and training

Four to six control functions in one

Pressure regulator function

Manual opening function standard on solenoid and pressure regulating valves

Full size 100 mesh strainer (2 ½” – 4” no strainer necessary)

All stop valve stems are in vertical up position

Simple, identifiable configuration

Eliminates flange gasket leak potential